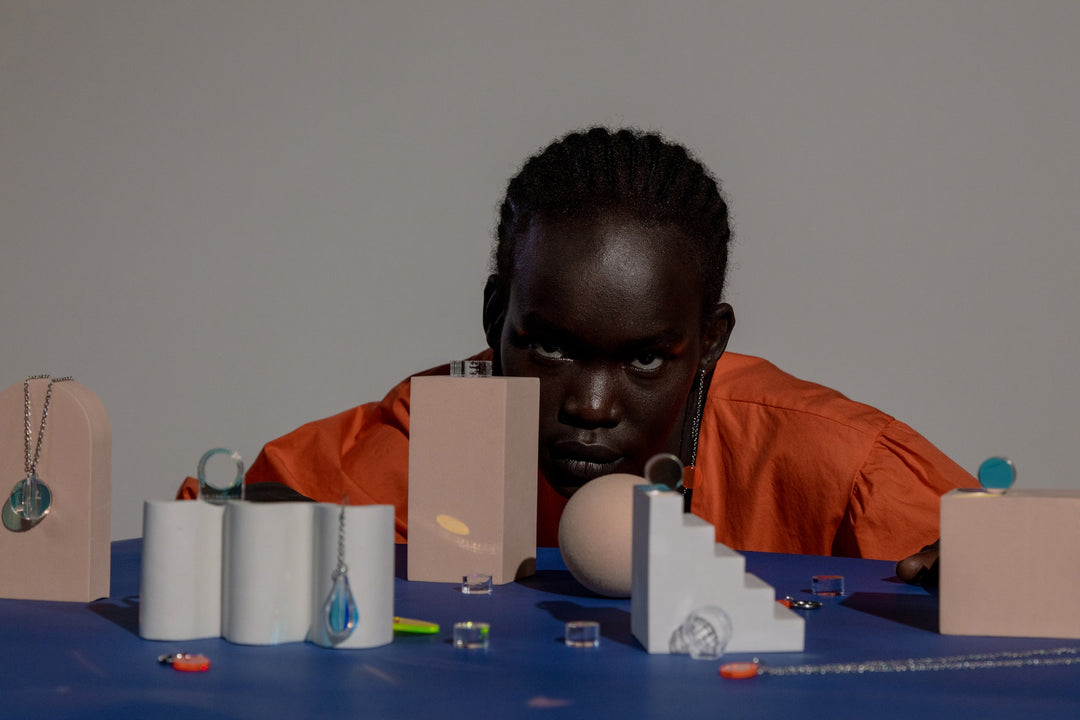

How jewelry is made step by step?

The jewellery manufacturing process involves several steps that are crucial for producing high-quality jewellery pieces. Here is a step-by-step guide to the jewellery manufacturing process:

-

Designing: The first step in the jewellery manufacturing process is designing the jewellery piece. This can be done by hand or using computer-aided design (CAD) software.

-

Creating a model: Once the design is finalized, a physical model of the jewellery piece is created. This can be done using a variety of methods, including 3D printing or wax carving.

-

Creating a mould: Next, a mould is created from the model. This can be done using silicone rubber, which is poured around the model and left to set.

-

Melting the metal: The chosen metal for the jewellery piece is then melted in a crucible using a furnace.

-

Pouring the metal: The molten metal is poured into the mould, which is then left to cool and harden.

-

Removing the jewellery piece from the mould: Once the metal has hardened, the mould is opened, and the jewellery piece is removed.

-

Cleaning: The jewellery piece is then cleaned using various techniques to remove any remaining mould material, such as sandblasting or chemical cleaning.

-

Polishing: The jewellery piece is polished using various techniques to achieve the desired finish, such as tumbling or buffing.

-

Setting stones: If the jewellery piece contains gemstones, they are then set into the metal using various techniques, such as prong or bezel setting.

-

Quality control: Finally, the jewellery piece is inspected to ensure that it meets the required standards for quality and craftsmanship.

The above steps are a general guide, and the specific jewellery manufacturing process can vary depending on the design and materials used.