Your Vision, Our Craft: Custom Jewelry Excellence

With our custom jewelry manufacturing services, we can create unique pieces to meet your exact specifications. We use only the highest quality materials and craftsmanship, ensuring a product of exceptional quality. Our designs are sure to bring sparkle and shine to your life!

Diverse Metal Choices: Exploring Your Range of Options

Dazzling Diamond Selections: Explore Your Spectrum of Choices

Certified Authenticity: Explore Certified and Non-Certified Options"

Versatile Plating Possibilities: Explore the Range of Finishes

Minimum Order Quantity (MOQ) Guidelines: Streamlining Your Ordering Process

- 925 Sterling Silver: Recommended 20-30 units per design

- 9K/10K/14K/18K Gold: Optimal range of 10-20 pieces per design

Efficient Lead Time Management: Ensuring Timely Delivery

- Sample Order: Completed within 8-10 days

- Bulk Order: Tailored to your designs and quantity, averaging 4-6 weeks

Seamless Shipping Solutions: Delivering Your Orders with Care

How Does It Work?

HOW TO GET MY JEWELRY DESIGNS MANUFACTURED

"Craft Exceptional Custom Jewelry with Our Manufacturing Services. Our skilled artisans meticulously create exquisite jewelry, using finest materials for unparalleled quality. Entrust us with your design, and watch it evolve into a masterpiece."

Visualizing Your Concept: Design, Sketches, or Reference Images

Unlock the Perfect Path to Manifest Your Unique Vision with Our In-House Design Services. Share your sketches or reference images to illuminate our designers with your project's essence, or entrust them to craft designs tailored precisely to your specifications. Together, we seamlessly transform your concepts into tangible reality.

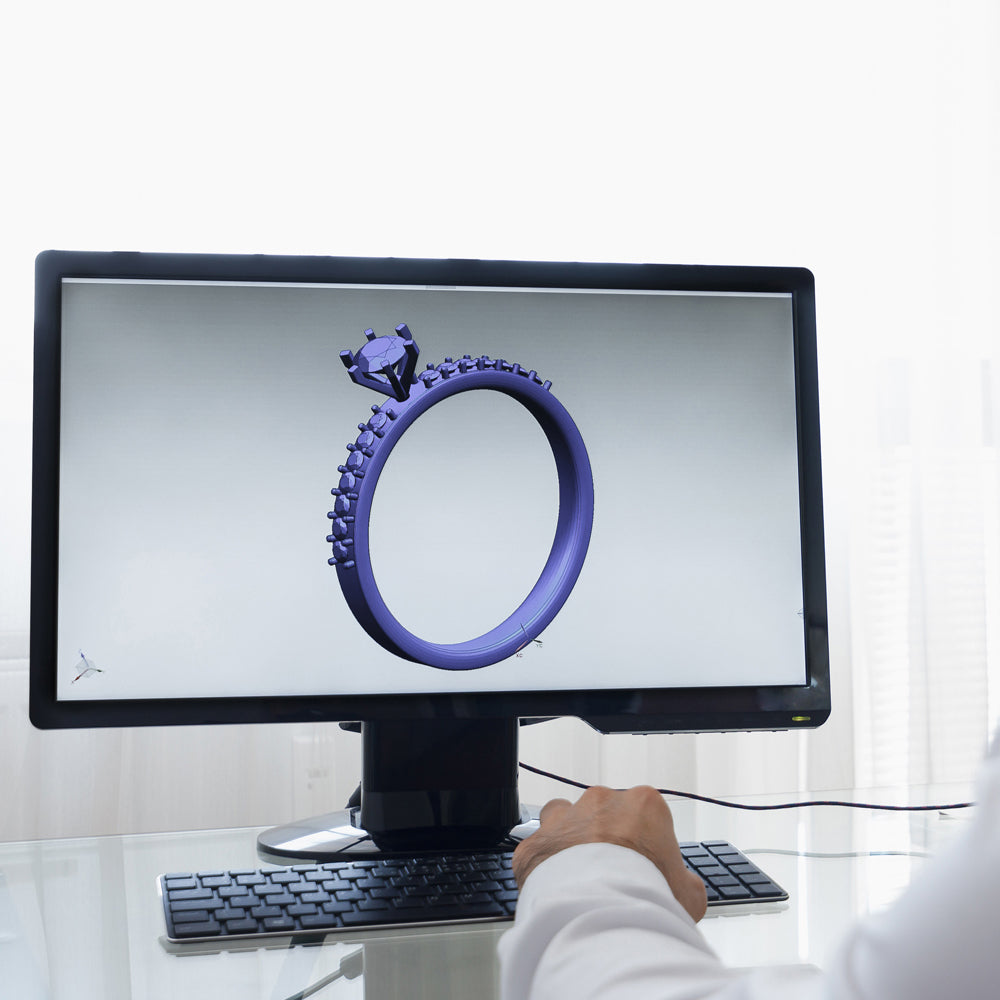

Precision Craftsmanship through CAD (Computer-Aided Design)

Experience the Art of Jewelry Design Brought to Life by Our Expert 3D Designers Using Cutting-Edge CAD Technology. Depending on intricacy, anticipate your digital rendering's completion within 1-7 days. Witness your envisioned custom jewelry design come to life with perfection.

Reviewing Samples, Approvals, and Revisions

Upon your CAD (Computer-Aided-Design) design approval, we seamlessly transition to the sample manufacturing phase. Should any adjustments be necessary, we diligently refine the sample until it achieves finalization. This meticulous process guarantees the delivery of an impeccable end product tailored to your specifications.

Efficient Bulk Production

Concluding the Journey: The Ultimate Stage in Our Specialized Jewelry Manufacturing Process

Embarking on the final phase of our meticulous jewelry manufacturing process, our bulk production service awaits. Expect a lead time spanning 15-30 days, contingent upon the intricacies of your order. Immerse yourself in the realm of top-tier jewelry production, guided by our profound professional expertise, and relish the pinnacle of craftsmanship.

Efficient Shipping and Timely Delivery

Safeguarded Shipment and Trustworthy Delivery

Rest assured, your exquisite jewelry items are meticulously packaged and entrusted to reputable third-party logistics services. Our unwavering commitment to reliable delivery guarantees the utmost safety and security for your precious products.